Brilliantly Resilient Label Solutions That Stick!

Custom printed, blank printable, and on-demand print & apply solutions for any industry. Hundreds of material, ink, and overlaminate options to choose from.

Shipped fast with superior print quality.

RFID – DOD – UID & UDI Labels

UID Labels

Learn about DLA’a First Destination Transportation and Packaging Initiative (FDTPI) already in Effect!

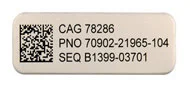

Millions of UID labels are used by contractors providing the military with products every day. IUID requires contractors to label each individual part that is shipped, label the unit or container holding the parts , as well as the package the individual units are being shipped in. This labeling system allows tracking the parts through the entire life cycle of the product. The requirements are outlined in a variety of specifications, but in general, 2d code is placed on each label, with a description of the product, in a particular format set forth by the military. An ideal IUID label will be perfectly square without rounded corners, have exceptional contract between light and dark print, dots will be round rather than oval and stay within the boundaries of the square. No dots should be found in the ‘quiet zone’, which is a small space around the outer perimeter of the label.

Verification

After the label has been formatted and printed, they must be verified. Label verification is a system that combines both hardware and software, that when used together, grades each label for readability. This ensures the specification has been met and that the label will maintain its integrity for the life of the product and stand up to the test of time when used in the field.

ImageTek Labels works with contractors everyday, to make sure that they understand the label process and shipments are sent on-time and meet compliance standards. If the labels are not compliant, deadline may be missed or worse, shipments rejected and sent back, leading to a possible loss of the defense contract all together. The IUID verification requirements can be found in.

- MIL-STD 130.

- MIL-STD 129P w/change 1

- DFARS 252.211.7003

- ISO/IEC Standard 15418

- ISO/IEC Standard 15434

- ISO/IEC Standard 16022

- ISO/IEC Standard 15415 – NASA Specific

At times, contractors may print the label on demand, in-house or perhaps, their labels have been supplied by another vendor. ImageTek Labels works with these contractors and will verify the labels for a minimal charge. A report and grade will be produced and sent back with the labels. In the event the labels are not compliant, ImageTek Labels can walk you through the steps that needs to be taken to assure the labels are printed correctly.

IUID Registry

Once the labels have been produced and verified they must be entered into the WAWF database. The registry was developed by DoD . The registry contains information about the product and shipment such as date of purchase, location, maintenance history etc. The system was established to aid the military in worldwide inventory procedures.

There are a variety of label requirements and contracts will state what standards need to be met. What is important to remember is that every label needs a 2d symbol, that symbol must be readable through the life cycle of the product and the label must be able to withstand environmental conditions and substrates must be complaint. Substrate compliance standards can be found in MIL-PRF61002b. The substrates can be anything from adhesive based, to laser marking or etching. Generally, laser etching and engraving are considered intrusive and the preferred methods for marking is an adhesive based label product.

Made from the most durable materials available, our UID labeling materials are the most widely specified in the defense industry. We have experienced UID staff, impeccable service and short lead times. ImageTek Labels is experienced in IUID Registration Service and our sales staff can help you to understand the UID specifications for your particular contract. Guaranteed to meet the MIL-SYD-130 and STANAG 2290, we are eager to work with you in helping you meet you UID requirements. ImageTek Labels can customize any label combination and artwork you need to meet the strictest of compliance regulations.

To view common Military Standards for IUID Labels click the links below.

UDI

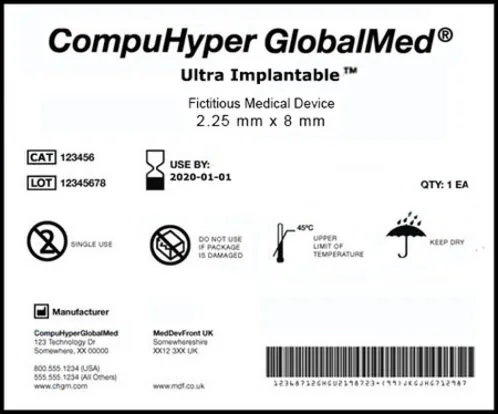

The Food & Drug Administration (FDA) has announced the final ruling that will require medical device manufacturers to label each unique medical device distributed in the U.S. with a UDI “Unique Device Identifier” label. The new regulation, under rule number FDA-2011-N-0090, proposes the development of a public database. This database will house information about each unique device and be made available for regulators, physicians and other interested parties to for the proposed safety related information for Class II and Class III medical devices.

ImageTek Labels is ahead of the compliance curve and stocks MedTek® UL recognized materials to meet this new requirement. Our materials offer thermal transfer topcoats with acrylic adhesive that will stand up to many of the harsh environments found in medical facilities. In addition to UL standards found in the new regulations there are chemical resistant standards. Approved materials for unique identification labels of medical devices must be resistant to many of the chemicals they will come in contact with in cleaning and sterilization. ImageTek Labels MedTek® UL approved materials comply with FDA ‘s 21CFAR Part 801 labeling guidelines in accordance with UL969 for medical device applications. They also comply with IEC 60601-1 3rd Edition (7/1/2013) marking and durability rub tests. Our LVS 7500® Verification System will scan your labels prior to shipping and deliver a compliance report to you with your labels to ensure quality and continued improvement traceability.

ImageTek Labels is here to help you understand the regulations and be prepared for the changes in your identification processes. For more information about the proposed changes please contact Bethaney Lanou, Technical Procurement Associate at (866) 403-5223 or email blanou@pcmanufacturing.com.

UDI

RFID Labels, the most technologically advanced label solution to date, are used to track products and assets through the WIP, identify individual components in mass quantities as well as for a wide variety of industrial and warehouse applications. RFID cuts costs and increases workflow. RFID labels are compiled of three major parts. The label or tag to mark the product or asset, the antenna that is built into the label or tag and encoded with specific product or process information and the reader that allows the parts or process to be identified. The need to individually identify the parts or process manually no longer exists.

RFID can control loss in retail environments, speeds up chain distribution, and tracks multiple items with less effort. RFID and the use for the process is vast. The limits of RFID are in the initial set up of the process. Our professional sales staff is available to work with you in determining you return and the value RFID can add to your business. RFID labels are used in a variety of industries like law enforcement and transportation and interest continues to grow. Line of sight is not required for RFID tracking and has proven to be a big benefit. Since RFID works by using a radio frequency signal. This makes tracking parts through production and distribution , easy and effective. They can be scanned in transport though facilities and in distribution. Major companies like Wal-Mart have added this system to their operations and at times require major suppliers to label their shipments RFID for distribution purposes. RFID systems integrators are experienced in helping companies set up their systems and integrate these systems with current practices.

Resources

Our Services

We have a team of highly skilled individuals who are waiting to help you!

Not sure about the material? Worried about auto-apply compatibility? Need

free samples?

Chat with a Label Guru.

Drop Us a Line.

(866) 403-5223

Request A Quote

"*" indicates required fields

Related Articles

Local Label Solutions – 3 New England Producers

From specialty foods, to craft beer and hemp producers, we’ve teamed up with some of the areas most well-known companies.

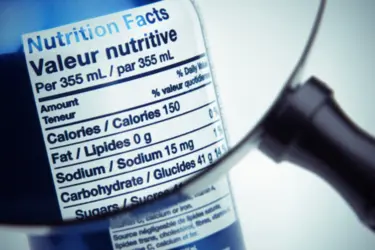

New FDA Nutrition Facts Label Rules

FDA Nutrition Facts Label requirements are being updated and require companies to modify their food, beverage.

Variable Designs – Perfect For Seasonal Label Printing

With ImageTek Labels state of the art digital printing technology, variable designs are a breeze. Don’t pay extra for custom plate charges.